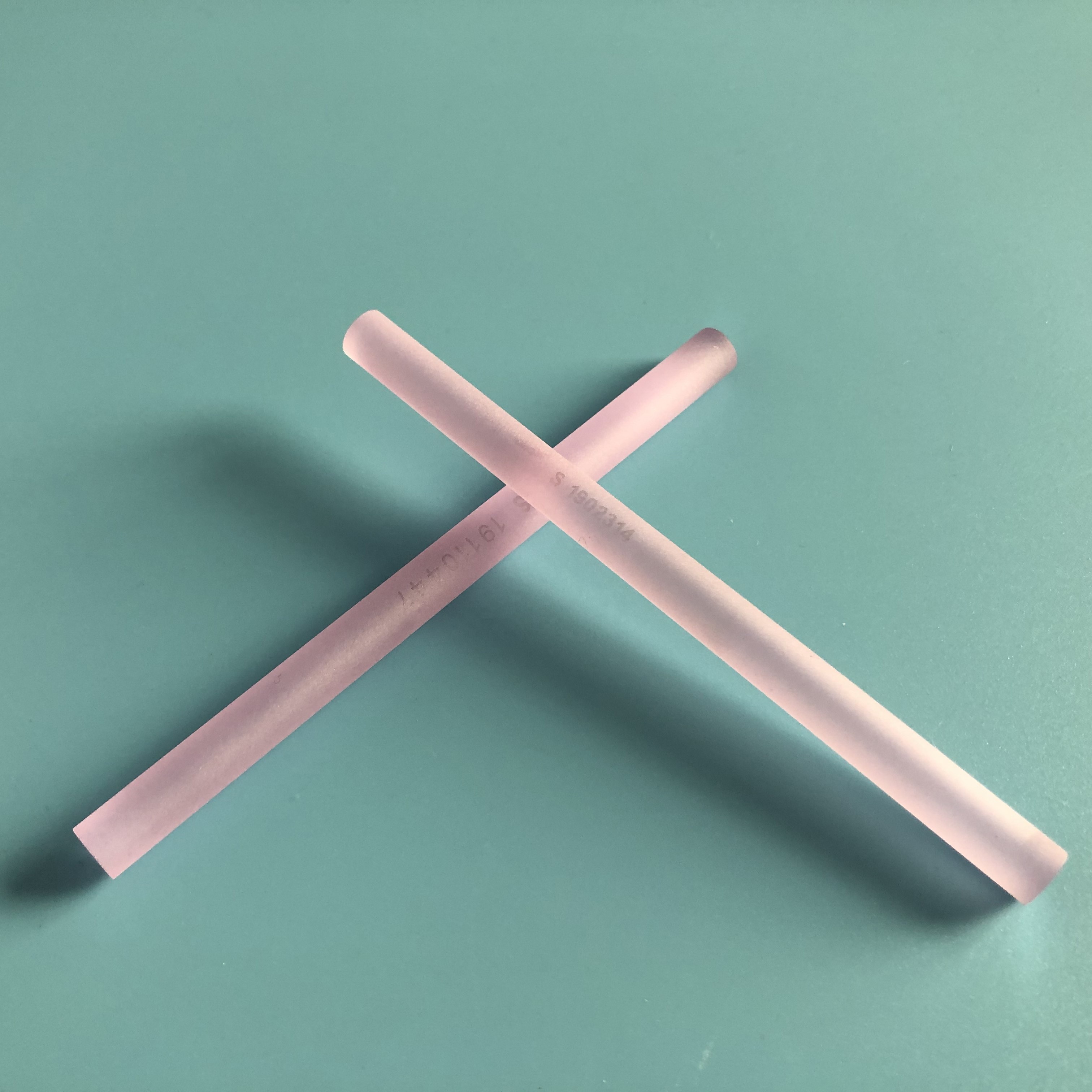

Ukunikezwa kwefekthri i-Ar Coated @1064nm ND YAG Crystal Rod ye-Laser Welding kanye Nomshini Wokusika

Ukunikezwa kwefekthri i-Ar Coated @1064nm ND YAG Crystal Rod ye-Laser Welding kanye Nomshini Wokusika

Amakristalu e-Nd:YAG, Nd:YLF kanye ne-Nd:YVO4 alungele ama-laser wesimo esiqinile asetshenziselwa ukushisela, ukusika kanye nezinhlelo zokusebenza ze-micro-machining.

Ukucaciswa

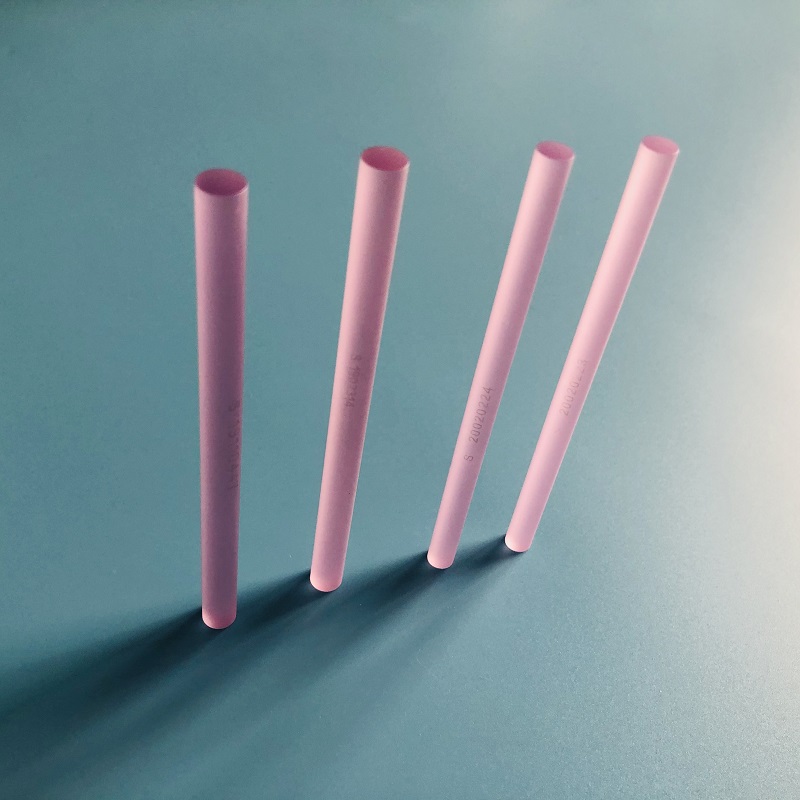

Usayizi wenduku: 3 - 30mm ububanzir (+0.0,-0.05);

Ubude:1 - 300mm ubude(+/-0.5);

Ama-Slabs:(3-50)mm ubude *(3-8)mm ububanzi *(30-200)mm Ukuphakama;

I-Dopant concentration:0.3% - 2.5%;

UbusoUkupholisha;

Izakhiwo:

| I-Doping (atm%) | 0.1%-2.5% |

| Ukuqondisa | <111>,<100>,<110>i-crystalline direction |

| Isakhiwo sekristalu | I-Cubic |

| I-Wavefront Distortion | λ/10 intshi ngayinye @632.8nm |

| I-Dimension Tolerance | Izinduku ezinodayamitha +0/-0.05, Ubude: ±0.1mm |

| UbusoQukuphila | 60/40,40/20,10/5 |

| I-Surface Flatness | λ/10@632.8nm |

| Isilinganiso sokuqedwa | 25dB ubuncane |

| I-Chamfer | <0.1mm@45° |

| Ukugqoka | AR/HR/PR enamathela phezu kwekhasimende's isicelo |

Izinzuzo ze-Nd:YAG crystals

Ukuzuza okuphezulu

Umkhawulo ophansi

Ukusebenza kahle okuphezulu

Ikhwalithi ephezulu yokubona

Ukulahlekelwa okuphansikwe 1064nm

Amandla amakhulu emishini

Ifanele izindlela ezahlukene zokusebenza (cw, pulsed, Q-switched,

Imodi ikhiyiwe, ukuphindwa kabili kobuningi)

Ifanele ama-laser amandla aphakathi nendawo

I-conductivity enhle ye-thermal kanye nezici zokushaqeka kwe-thermal

Izicelo Ezijwayelekile

Ukumaka nge-laser;

Umuthi we-Laser;

Ukulungiswa kwe-laser;

Ukusika i-Laser;

I-laser welding.

Imikhiqizo ebonisiwe